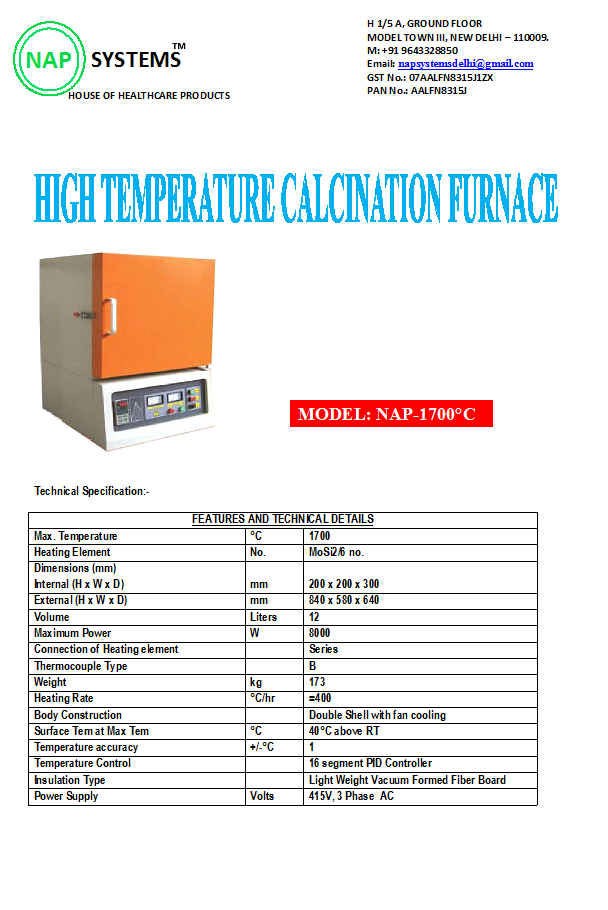

High Temperature Calcination Furnace

Product Details:

- Humidity % 85%

- Dust Low dust emission

- Dust % <0.02%

- Noise Level <60 dB

- Ventilation Inbuilt ventilation system

- Efficiency (%) >94%

- Material Mild Steel and Ceramic Wool Insulation

- Click to View more

X

High Temperature Calcination Furnace Product Specifications

- 85%

- Low dust emission

- <0.02%

- Inbuilt ventilation system

- <60 dB

- 220V/380V/415V

- >94%

- Mild Steel and Ceramic Wool Insulation

- 5-100 kg per batch (customizable)

- Blue / Grey (customizable)

- 12-30 kW

- PID Temperature Control, Programmable Timer, Safety Interlock, Over-temperature Protection

- Low Maintenance

- High Temperature Calcination Furnace

- Automatic

- 600-1500 kg

- Atmospheric

- Max Temperature 1700C

- Ceramic fiber insulation, no filters required

- Panel Display and Remote System Connectivity

- 50/60 Hz

- Digital Microprocessor Controller

- 1200*800*1550 mm (standard, customizable options available)

- Optimized, high thermal efficiency

- Floor Mounted

- Ceramic, Metallurgical, Laboratory, Research, and Industrial Usage

- Does not apply

High Temperature Calcination Furnace Trade Information

- Cash Against Delivery (CAD)

- 20 Per Month

- 30 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- Asia

- All India

Product Description

Grab the sterling value of this High Temperature Calcination Furnace, designed for venerable efficiency and safety in demanding environments. Personalise your operations with chamber volumes from 32L to 80L and automatic PID temperature control, reaching up to 1700C with precision (+/-1C). Featuring Kanthal A1/NiCr heating elements, robust mild steel body, and ceramic wool insulation, this top-ranking equipment offers a front-opening double-walled door, digital LED/touch screen, and essential alarms for overcurrent and high temperature. Energy-efficient with excellent safety interlocks, its ideal for laboratory, ceramic, metallurgical, and industrial usage in India.

Primary Applications, Competitive Advantages & Features

The High Temperature Calcination Furnace stands out for its use in ceramic, metallurgical, laboratory, and research fields, as well as industrial environments. Its primary competitive advantages include superb temperature accuracy, customizable batch capacity, and robust safety systems such as auto shutdown and advanced alarms. Additional features like rapid heating rates, inbuilt ventilation, low dust emission, and energy efficiency further enhance its operational excellence. Front-opening, double-shelled and programmable, this furnace embodies versatility and reliability for varied professional usage.

Certifications, Delivery and Supply Information

Our High Temperature Calcination Furnace is manufactured to meet stringent industry standards and certifications, ensuring safety and performance. Delivered securely and on schedule, shipped goods are packaged for optimal freight protection. Standard supply ability accommodates diverse order volumes, meeting requirements of dealers, distributors, exporters, and end users alike. With prompt lead times and dedicated after-sales support, you can trust in the fast delivery and seamless installation of your furnace, anywhere across India and beyond.

Primary Applications, Competitive Advantages & Features

The High Temperature Calcination Furnace stands out for its use in ceramic, metallurgical, laboratory, and research fields, as well as industrial environments. Its primary competitive advantages include superb temperature accuracy, customizable batch capacity, and robust safety systems such as auto shutdown and advanced alarms. Additional features like rapid heating rates, inbuilt ventilation, low dust emission, and energy efficiency further enhance its operational excellence. Front-opening, double-shelled and programmable, this furnace embodies versatility and reliability for varied professional usage.

Certifications, Delivery and Supply Information

Our High Temperature Calcination Furnace is manufactured to meet stringent industry standards and certifications, ensuring safety and performance. Delivered securely and on schedule, shipped goods are packaged for optimal freight protection. Standard supply ability accommodates diverse order volumes, meeting requirements of dealers, distributors, exporters, and end users alike. With prompt lead times and dedicated after-sales support, you can trust in the fast delivery and seamless installation of your furnace, anywhere across India and beyond.

Specification

|

FEATURES AND TECHNICAL DETAILS |

||

|

Max. Temperature |

C |

1700 |

|

Heating Element |

No. |

MoSi2/6 no. |

|

Dimensions (mm) Internal (H x W x D) |

mm |

200 x 200 x 300 |

|

External (H x W x D) |

mm |

840 x 580 x 640 |

|

Volume |

Liters |

12 |

|

Maximum Power |

W |

8000 |

|

Connection of Heating element |

|

Series |

|

Thermocouple Type |

B |

|

|

Weight |

kg |

173 |

|

Heating Rate |

C/hr |

400 |

|

Body Construction |

|

Double Shell with fan cooling |

|

Surface Tem at Max Tem |

C |

40 C above RT |

|

Temperature accuracy |

+/-C |

1 |

|

Temperature Control |

|

16 segment PID Controller |

|

Insulation Type |

|

Light Weight Vacuum Formed Fiber Board |

|

Power Supply |

Volts |

415V, 3 Phase AC |

FAQs of High Temperature Calcination Furnace:

Q: How is the High Temperature Calcination Furnace installed at the facility?

A: The furnace is floor-mounted and designed for straightforward installation with onsite or remote technical support provided. Universal electrical compatibility (220V/380V/415V) ensures seamless setup, and our team assists with commissioning to ensure safe operation.Q: What key safety features does this furnace include?

A: This top-ranking calcination furnace is equipped with auto shutdown, overcurrent and temperature alarms, safety interlocks, and robust double-walled construction to maximise operator safety during high-temperature operation.Q: Where can the High Temperature Calcination Furnace be effectively applied?

A: It is ideally suited for ceramic, metallurgical, laboratory, research, and broad industrial applications, offering versatility and customization for a wide range of professional environments.Q: What are the primary benefits of using this furnace?

A: You gain precise temperature control, high heating efficiency (>94%), low maintenance requirements, and reliable safety features. Its customizable batch capacity and remote connectivity further streamline operations, adding substantial value to your process.Q: How is delivery and installation support managed after purchase?

A: Once shipped, the goods are covered for safe transport and timely delivery by freight carriers. Installation guidance is provided either onsite or remotely, accompanied by prompt after-sales service and technical assistance to ensure optimal functioning.Q: What is the process for customizing the furnace for specific batch or chamber volumes?

A: When placing your order, specify your required batch capacity (5100 kg) or chamber volume (such as 32L, 50L, or 80L). Our manufacturing team will tailor the furnace to your precise specifications, optimizing it for your unique application.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Furnace' category

|

NAP SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |